ROXSTA smart integral ensures optimum organic quality

On the outskirts of Bad Vilbel lies the old cultural monument Dottenfelderhof, just 25 km from our headquarters in Altenstadt. The estate was first mentioned in 976 as a monastery manor and has been managed by the Dottenfelderhof farming community as biodynamic agriculture as per Demeter standards since 1968.

The farm features an extensive operation: varied agriculture, fruit and vegetable growing, livestock farming, an agricultural school, research, marketing and a broad programme of events. In the dairy, milk is processed into cheeses and dairy products, some of which have won national awards. The farm’s own grain is refined into various baked goods in the wood-fired bakery in the monastery garden. Together with freshly harvested fruit and vegetables, a wide range of organic produce and products from other Demeter farmers in the region, the farm’s own products are sold in the farm shop and at markets in the surrounding area.

The farm shop is an economic mainstay for the Dottenfelderhof. It initially began in 1973 in a converted cellar with the sale of milk and bread, . Garden and field crops were soon added. The range on offer grew steadily and more space was needed. In the 1980s, the farm community converted the former cowshed into a farm shop and moved some of the produce to a separate storage on the farm. As the product range grew, it soon became clear that another move was inevitable.

Double the space – all under one roof

After years of planning, the development plan was finally completed in early 2019. From there, everything progressed very quickly and the new farm shop opened on 28 May 2020. The new premises feature a sales area that is nearly twice as large at almost 800 square metres and a further 700 square metres for cold stores, storage areas, offices, social rooms and parking spaces for market cars. The building was constructed on a plot of land directly in front of the farm entrance. As a result, customers – around 400 per day – no longer have to drive to the farm along its narrow tracks, where everything used to converge: customers coming on foot, with bicycles, prams, cars, vans and so on can now park easily in the new shop’s large car park.

“The situation is now uncongested,” as Peter Hollerbach (farm shop manager) puts it. “Separating the farming and sales sides of the business not only benefits the farm’s 100 residents, but its 150 employees too. Integrating the warehouse and cold storage rooms is particularly advantageous for operational processes. Thanks to the new building, there is no longer any need for intermediate storage at various points across the farm. Products are delivered directly to stalls, counters and shelves or can be easily loaded into sales vehicles for weekly markets.”

Ecological through and through

When planning the new building, the aim was not only to better present the goods and create more efficient structures – environmental concerns were also particularly important. The entire building was mainly constructed from wood and was designed to meet the low-energy standard. Lots of glass on the walls and roofs provides plenty of daylight, therefore there is little need for artificial lighting. The electricity is largely supplied by the farm’s own combined heat and power plant, and the waste heat from operating the refrigeration plant is used for air conditioning and hot water preparation.

Implementing refrigeration – holistically solved with CO2

The refrigeration solution has been implemented by RS Kälte-Klima GmbH from Sulzbach/Saar. Frank Redda (RS Managing Director): “We were delighted to receive the order from Dottenfelderhof! An ecological approach is completely embraced here, which fits perfectly with the current refrigerant situation, of course. The farm is a pioneer in terms of sustainability and efficiency. Right from the beginning, it was clear that only a holistic solution using the natural refrigerant CO2 could be considered here. We have been working closely with TEKO for a long time, which is why we chose the TEKO series solution ROXSTAsmart integral – an all-in-one system offering cooling, heating and air-conditioning. When developing the ROXSTAsmart integral, TEKO focussed on simple handling yet extensive, sophisticated functions, which our local service staff were able to endorse. Commissioning went smoothly in just one day. Since we already had good experiences with a comparable TEKO unit in another organic shop, we did not expect anything else.”

The old farm shop was cooled by several individual machines that were installed decentrally in different parts of the farm. In contrast, the ROXSTAsmart integral was installed as an indoor installation in a central machine room within the new building, which reduces noise levels considerably. The buffer storage tank and the feed pump for the various cooling/heating circuits are also located here.

Wurm control electronics

The organic farm’s lovingly homemade products necessitate the highest standards of refrigeration and control technology. The quality of the products should in no way be affected by being stored in the refrigeration units.

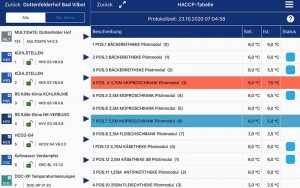

In this instance, the correct storage temperature, the lowest possible dehumidification of the goods and gentle defrosting cycles for the refrigeration cabinets all play a key role. These requirements are met by the FRIGOLINK solution offered by our partner Wurm Elektronische Systeme from Remscheid. This is yet another reason for equipping even the smallest of cooling points with these benefits. In total, the project has over 22 cooling points, all of which have been fitted with FRIGOLINK. Energy consumption is thus another of the project’s focal points.

In building services engineering, too, all control technology gears merge together since heating, air-conditioning and ventilation technology is also controlled by the Wurm system. In the case of such interlinked systems, which ensure all project requirements are met, we speak of “integral systems”.

“Another important aspect is related to quality assurance requirements. Wurm Systeme offers customised solutions for all areas of interest. At Dottenfelderhof, we have opted for the proven Frigodata XP analysis tool and the FRIDA app. Using the FRIDA app, the service technician can operate the system via their smartphone or tablet. By means of internet-based and VPN-encrypted remote data transmission, appropriately authorised personnel have remote access to the system, enabling direct intervention without having to travel to the site,” explains Frank Redda.

Sustainability from A to Z

The waste heat from the refrigeration plant is used to heat and air condition the retail store, the offices, the recreation room and the warehouse. This corresponds to 90 to 95% of the required heat output. A heat pump is switched on to cover the remaining 5 to 10%. Via an intermediate circuit with pump, the heat/cold reaches a 500-litre storage tank and is distributed from there via ceiling air units to the appropriate points in the retail store. GTM’s innovative building services engineering makes this mere child’s play. The system organises the hydraulic balancing of the individual heat exchangers completely automatically by means of calculation algorithms, so that the temperature can be controlled exactly and highly efficiently. The building services concept was planned and implemented by Kratschmayer Luft-Wärme-Klima GmbH from Waldenburg.

The WHITELINE gas cooler supplied is designed as a combination unit with heat pump evaporator. In order to use all the waste heat in its entirety, a gas cooler bypass is switched on in winter when outside temperatures are low. The heat pump evaporator is also used if the outside temperature falls further below the set temperature. Thus, we achieve a total heating capacity of 70 kW using this unit. By combining the two units, the footprint is reduced and noise emissions are very low at 30 dB(A) at a distance of 10 m. Moreover, waste heat from the gas cooler is used to defrost the heat pump package efficiently and economically without additional electrical heating.

In summer, the same network of pipes transports cooled water to the ceiling units and air conditions the retail store to a comfortable temperature.

In addition, the refrigeration plant is equipped with the Wurm METEOLINK module, which enables anticipatory control of the heating or cooling mode. This increases operational safety and comfort immensely.

Financing

When it comes to support in the field of energy efficiency, ecogreen Energie is our go-to contact. With over 10 years of experience, the subsidy experts support companies to finance energy efficiency projects. The Dottenfelderhof project was another that was financed and implemented as a result of ecogreen, RS Kälte-Klima and TEKO working together. The project shows which funding possibilities are available for farm shops and how the additional costs associated with more efficient refrigeration technology can be absorbed. In total, around 10% of the Dottenfelderhof investment costs were subsidised. Marcel Riethmüller (Managing Director of ecogreen) says: “Our aim is to provide companies with quick and easy access to funding. We were able to achieve this together with our partner companies thanks to excellent cooperation.”

Description of the system technology

Facts & figures

- Total area approx. 1,500 m2

- A total of 22 cooling points:

– 8 ref. counters (butchery/bakery)

– 9 cold stores (dairy/fruit & veg/cheese/meat)

– 1 fresh meat preparation

– 4 wall-mounted refrigerated shelves (dairy/meat)

ROXSTAsmart integral

Integrated system for cooling, heating and air conditioning

- Refrigerant R 744 (CO2)

- Medium temperature cooling

3x Frascold compressors (1st compr. with FC)

47 kW (t0 -5 / tGC out 38 °C) - Heating

70 kW (tWater in/out 25/40 °C) - Air conditioning

45 kW (t0 2 / tGC out 38 °C)

Controls

Wurm control electronics FRIGOLINK HCO2

Special features

- Heat recovery C2Hbasic incl. heat pump

- Controlled suction gas heat exchanger for MT, heat pump and air conditioning

- WHITELINE gas cooler/heat pump evaporator combination with 3 EC fans: 310 kW (tamb 35 °C / tGC out 37 °C)

- 10x WHITELINE CO2 wedge coolers

Image sources: RS Kälte-Klima / jannasfotografie / Bernd Liebermann

News

News