Article from the Wurm magazine FRESH UP 02 2021 (published in summer 2021)

Ongoing procurement crisis for materials and components is also affecting our production facility

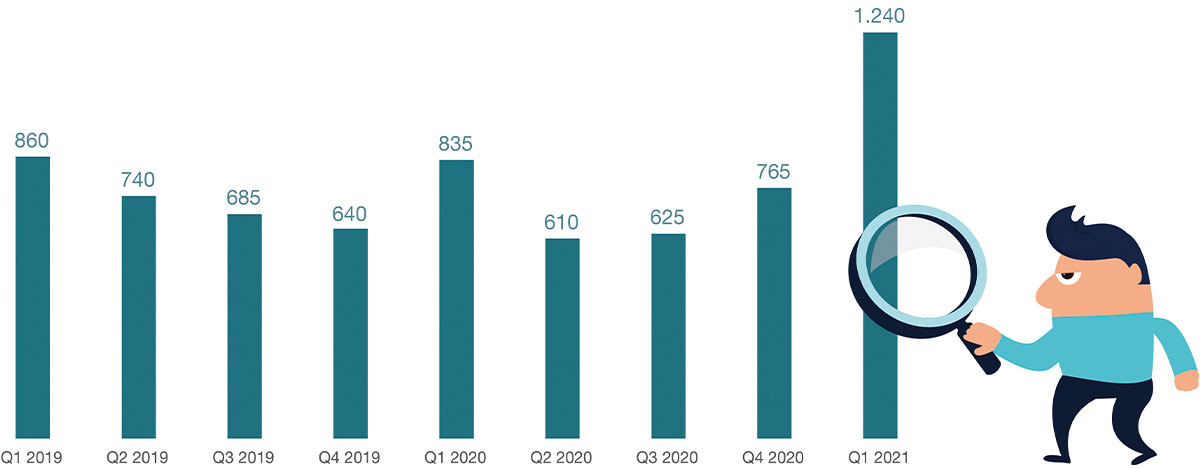

In fact, the material bottlenecks for components, raw materials and accessories have occurred at a level far exceeding past cyclical waves of demand (allocation). There has never been a time when so many companies both worldwide and industry-wide have been affected; even the listed “big players” have had to stop some of their production. There has never been a time when the supply of so many different materials has come to a halt, if not to a standstill, so that even cables are hardly available for our switchgear construction, for example. And there has never been a time when the world economy has been hit by so many different exceptional events as it is now – from the pandemic and its consequences to Brexit and the booming Asian economy.

Thanks to its high stock policy (something not typical in the industry) Wurm can ensure its deliveries, and we have thus been able to supply anticipated allocation phases. But, as with almost all market participants, our room for manoeuvre is now drastically limited in the aggravated situation. Since the ability to deliver (and price reliability) for our customers and partners takes top priority at Wurm, we are pulling out all the stops to keep the effects as low as possible for you. Whether through continual demand analyses in exchange with you, through constructive adjustments in our development department or situation-dependent prioritization of the production lines.

Operations Manager Marius Kurtz has been with Wurm since 2011 and ensures that all relevant processes in the entire company function smoothly and are optimised if necessary. With his in-depth knowledge of all areas of the company, in this interview he answers questions about the coronavirus effects on Wurm:

The critical procurement situation harbours so many unpredictable influencing factors. So how is Wurm dealing with this?

A high degree of creativity and flexibility is required. If well-established processes are not working, we try to find the best possible solution. If, for example, a certain component is unavailable, other parts of the same design must be found to match. If a supplier fails, we have to procure new sources. Support from colleagues at Bitzer China, who provide us with direct access to the manufacturer, is therefore all the more valuable. Nevertheless, with some devices, our hardware development needs to produce redesigns under tight time pressure. This is how we are able to use components with different technical properties but that have the same high quality and reliability.

How can one still plan and act with so many international imponderables?

At present, this is more difficult than ever. For example, the coronavirus is also affecting the sales situation: Since the demand for preliminary products has drastically increased due to the pent-up demand, some of our competitors are no longer able to deliver. At Wurm we are therefore seeing significantly higher demand, but this demand is not predictable in the least. In addition, due to the pandemic, we have had to significantly reduce the number of jobs in switch cabinet construction in order to meet the safety margins. To compensate for this, we have rented an additional production area in Remscheid. All this taken together means an enormous logistical challenge with a significant increase in coordination effort. We have to be even better at planning what, where and when we will produce – and react flexibly at any time if the situation requires it. Unfortunately, due to the coronavirus, we often have to be reactive rather than proactive. In addition to the overall tension, solution-oriented work demands a great deal from each individual.

We very much hope that the situation will ease noticeably once again in the coming year – and that we can concentrate once more on the further development and new development of products. Because we would far rather tell you about our exciting new products.

News

News