Frigodata XP software has helped users manage their units for over 20 years. Over the course of its development, it has transformed into a powerful tool with many features. The software developers behind Frigodata XP have always strived to adapt the features to satisfy user requirements. As a result, useful features are continuously added to the primary function – on-site and remote unit parametrisation and analysis.

Frigodata XP – features:

- Fault transmission

- Automatic data requests

- Connection monitoring

- Process displays

- Oscilloscope

- Track allocation for plot data

- Log (p)-h diagram with live data

- Log for goods status and setpoint changes

- Clear display of fault lists

- Overview of Frigotakt Plus, defrost manager and HACCP (Hazard Analysis Critical Control Point)

- Maintenance group allocation

- etc.

Frigodata XP master stations are now capable of managing the entire project core centrally in service companies. This has enabled several hundred projects to quickly accumulate in the database over the years in large companies.

Field service technicians typically only have a fraction of these projects saved on the database of their laptops. In order to create a new project, passwords are first requested. Once a new project has been successfully created, the connection settings (e.g. IP addresses, local connection) are configured in order to first connect to the project and then upload the entire database from the project onto the service laptop. In the case of emergency service calls, the service technicians usually remotely access the master station in the office in order to perform an initial analysis and synchronise the project with their service laptop.

A job that usually takes between 15 and 30 minutes, depending on the size of the project, and frequently involves a trip to the coffee machine. 🙂

Office-based employees, who have largely been required to work from home during the Corona pandemic, are now faced with the same issue. They are also required to synchronise projects onto their laptops using the method described above. As the employees generally connect to different projects several times throughout the day and remote access to the company’s Frigodata XP master station may already be blocked by another colleague working from home, a practical solution was urgently required to support both field service technicians and in-house employees working remotely.

Synchronisation with the new DataCenter

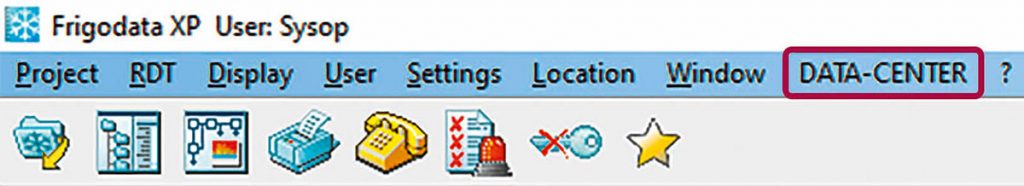

This is where the new DataCenter feature comes in. The feature has been available since the most recent update to software version 4.7.0.

Link to the Frigodata XP update: https://update.frigodata.net/#FrigodataXP

A connection to the DataCenter facilitates access to all master data, passwords, logs and fault lists for the activated projects in the DataCenter and allows these to be synchronised with the Frigodata XP data root at the push of a button. A valid and identity-linked Frida licence is required to use the DataCenter

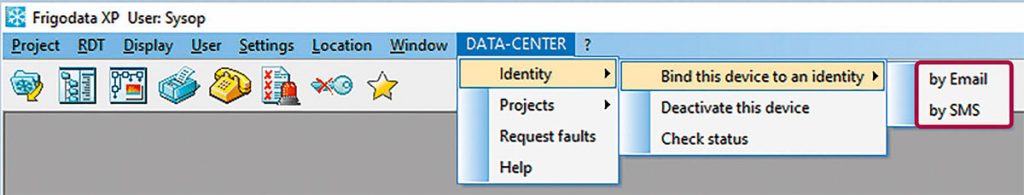

Select either email or SMS to link the Frigodata XP licence to your identity. Depending on the permissions stored in the security centre (service company/permissions for maintenance groups/access permissions, read or write permissions, etc.), the required project can quickly and easily be synchronised from the DataCenter onto your laptop.

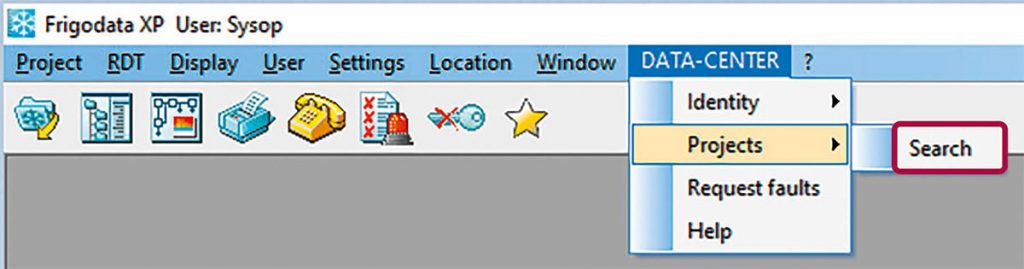

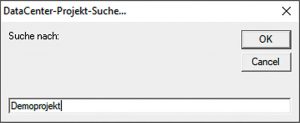

Simply use the search feature after a successful connection.

Find the required project at the drop of a hat with the keyword search.

Double-click on the project to start the download. After roughly one minute, your current project will be uploaded into the database. The DataCenter records all logs and parameter data in addition to the master data (name, IP address, passwords,etc). You can now get started with your work right away once the connection to the retail store has been established instead of waiting for lengthy read processes.

We hope that this new feature makes your daily tasks easier with Frigodata XP, both when working remotely and responding to service calls on-site.

Employee offboarding

An additional useful feature of the DataCenter concerns employee offboarding. When an individual approved to use the DataCenter leaves the company, a simple phone call to TEKO or Wurm suffices to deactivate the employee. Otherwise, he will be able to take the project – including the setpoint adjustment – to your competitors and still be able to access the unit. Wurm is currently working on a platform to facilitate quick and easy internal management of employees and their permissions by refrigeration companies.

Have you discovered the FRIDA app?

Frigodata XP has made a name for itself as a reliable, helpful software and is constantly updated with innovative new features. In addition, many Frigodata XP users also benefit from in-app support with the mobile FRIDA app. Contact us today if you are interested in the FRIDA app and would like to learn more about its features in combination with Frigodata XP. Learn more by visiting our partner Wurm’s website:

https://www.wurm.de/nl/gegevensbeheer-en-software#frida

https://www.wurm.de/sites/default/files/downloads/folder/Flyer_FridaApp_E.pdf

News

News