Report by Andreas Schmitt (Head of Research & Development) and Lukas Beier (Technology Development)

The history of industrial refrigeration technology has been shaped by many attempts to render commercial refrigeration efficient. In addition to various unit constellations, different refrigerants and refrigerant mixtures have been used. After almost 150 years of industrial refrigeration, a serious intervention in the market came into force with the establishment of the F-Gas Regulation and the Ecodesign Directive. This upheaval in the field of refrigeration is more pertinent than ever. Due to the shortage of refrigerants and the prohibition of the use of certain refrigerants, a rethink became necessary and inevitable. Not only manufacturers of refrigeration units, but also operators and refrigeration unit builders had to rethink their applications and allow for new orientations.

Many years ago, we at TEKO began to dedicate ourselves to the subject of “natural refrigerants”. What started about 15 years ago as a test project with limited demand has developed over the years into our core competence. With our CO2 series, we offer future-proof and environmentally friendly solutions in the megawatt range of less than 1 kW to large industrial solutions.

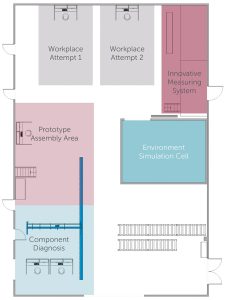

Our main focus is always on innovative and standardized solutions. Our research and development department often lays the foundation for possible innovations. Based on theoretical considerations, our development team plans projects and implements these in practical test assem-

blies. This implementation takes place within the company’s own test laboratory. In addition to material tests and smaller test setups, the test laboratory’s area of responsibility extends to complete unit tests.

TEKO & Wurm – Working together for the best result

Our main priority is to deliver the best possible quality with the highest efficiency. Therefore, the control systems of our long-standing partner Wurm Systeme is an integral part of our research and development. Historically, we have been able to jointly develop control strategies and innovative solutions while supporting each other in our partnership. Some Examples of this are the estimated product temperature of the goods, Smartflow+ and Frigotakt+.

Our main priority is to deliver the best possible quality with the highest efficiency. Therefore, the control systems of our long-standing partner Wurm Systeme is an integral part of our research and development. Historically, we have been able to jointly develop control strategies and innovative solutions while supporting each other in our partnership. Some Examples of this are the estimated product temperature of the goods, Smartflow+ and Frigotakt+.

In order for us to keep up with the rapid pace of technological developments in our industry and make the right future-oriented investments, we have upgraded our test laboratory, leading the industry both locally and internationally in product and technology development.

Innovative Measuring System

We have set up an innovative measuring system which allows for component- and manufacturer-independent data acquisition. This step enables the central documentation of all the relevant measuring points including operating data from different components, such as frequency converters. In addition, several load profiles can be simulated via the system in order to more precisely test the dynamic behaviour of a unit.

Component Diagnostics

The expansion of the premises allowed us to integrate the “Component Diagnostics” area into the test laboratory. In this way, we can gain immediate insights from the test runs and have the opportunity to incorporate these in an individually adapted way into the development process. Not only can we determine damage or wear on compressors, but also on other components such as valves, and identify possible causes of damage here at TEKO and initiate the necessary steps.

Environmental Simulation Cell

In order to specifically examine the effects of different ambient conditions on heat exchangers and the resulting behaviour of the unit, it is necessary to simulate air humidity and temperature. For this purpose, we set up an environmental simulation cell in our in-house test laboratory at the beginning of the fourth quarter of 2021. With a size of 6x8x5 meters, this cell offers sufficient enough space to create various ambient conditions and is ideally suited for the test operation of refrigeration units. This investment allows us to put our system solutions through their paces under real summer and winter conditions and gain information on pulsations, vibrations and sound emission.

With a view to the test options gained, this step was necessary in order to be able to react individually to the various customer-specific challenges in the future.

Installation Space for Prototypes

With the change in technical possibilities, it has become necessary to implement various reality-based approaches – not only through simulated test setups, but also through real prototypes. For this purpose, we have made a prototype assembly area part of the test laboratory. New types of units as well as optimisations of existing units will be tested here, also with regard to the series production capability of our products. Our focus is on a sustainable way of working. It was therefore important to develop a modular connection technology that enables a resource-saving implementation of different assemblies and pipe designs. This is based on prefabricated sheets, pipes and transitions that are connected to one another by

means of detachable screw connectors.

Conclusion

All in all, we can say that TEKO has not remained unaffected by technical change, and the necessary steps have been taken

to meet the expanded requirements.

News

News