Temperature documentation 2.0

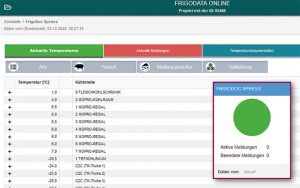

HACCP*-compliant temperature monitoring in supermarkets is indispensable to ensure the quality of goods, both in terms of consumer protection and food hygiene. To provide operators and quality managers with a quick and direct overview of the current temperature readings during their day-to-day business, our partner Wurm Systeme has developed a web-based solution: Using FrigoDoc Xpress, the manager of a retail store or branch outlet can see at a glance whether and where there are current temperature deviations in one of their stores.

Many of our customers have been using the established temperature documentation systems from Wurm Systeme for over 15 years. The requirements for such systems are subject to constant change. Quality assurance is becoming increasingly important and offers clear benefits for both consumers and operators alike:

Due to recurring scandals in food retail, end consumers are unsettled and looking for trustworthy suppliers who handle food and its storage responsibly.

Such systems are also beneficial for operators. On the one hand, by using suitable systems, they can gain their customers’ trust and safeguard their status as suppliers. On the other hand, temperature deviations can be detected promptly and appropriate countermeasures can be initiated – even before goods may be lost. This also avoids unnecessarily wasting food resources.

As far as quality assurance (QA) is concerned, operators of multiple branches are usually organised centrally. This ensures the quality across an entire company network and sets the same standards everywhere. Thanks to FrigoDoc Xpress, it is possible to check and evaluate all locations of a branch network at a glance. Using a secure VPN connection, the system retrieves and updates temperature documentation data every 10 minutes. Current temperatures are stored on two TÜV-certified, redundant Wurm servers and additional security backups are performed daily. This greatly increases data security and speed compared to storage on a local PC.

In addition, when it came to former “single-user solutions”, operators had to take care of data back-ups, functional checks and software and operating system updates on their own. Alongside the digital data, system printouts were often created so there was a back-up in case of IT failures. Thanks to this central, web-based system, the operator hands over this responsibility to Wurm and also takes another step towards running a paperless office.

The web application means the responsible person is independent of time, place and the local PC. Whether in the retail store, online, on the road or from the head office, HACCP temperatures can be read quickly, easily and reliably at any time, regardless of location or platform. The simple graphic interface makes it easy for users to operate the system quickly and intuitively on all end devices.

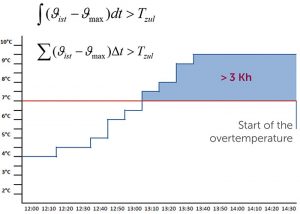

The status of the retail store is represented using a simple traffic light system. A green traffic light immediately signals that all temperatures are OK. A red traffic light indicates that there are deviations from the specified target values which must be checked and corrected. An underlying algorithm ensures that only relevant temperature deviations result in a warning message.

The determined temperature values are not simply air temperatures, but actually determined representative product temperatures. The Wurm control thus offers different measuring methods.

Furthermore, FrigoDoc Xpress makes it possible to monitor cooling points that are not equipped with Wurm refrigeration controllers (e.g. refrigerators, plug-in refrigeration cabinets etc.). They can be retrofitted with either wired sensors or radio sensors, and thus monitored as a virtual cooling point within the system. For cooling points that do not allow for any of the applications described, measurements can be taken manually and the results digitised in the system.

The simple and clear user interface provides users with a quick overview of their own systems and the responsible QA officers can create and adjust comprehensive product group assignments themselves.

These days, numerous operators already trust the FrigoDoc Xpress solution from Wurm. Over 2,500 branches have already been integrated since the system was introduced in 2015. Thanks to Wurm’s intelligent FrigoData online software solution, data from approximately 14,000 projects are retrieved daily across borders, all of which is compatible with FrigoDoc Xpress. The dial-up connection, which is generally available anyway, makes it possible to connect to FrigoDoc Xpress simply and cost-effectively.

* HACCP = Hazard Analysis and Critical Control Point

News

News