INNOVATIVE TECHNOLOGY FOR THE REFRIGERATION SYSTEMS

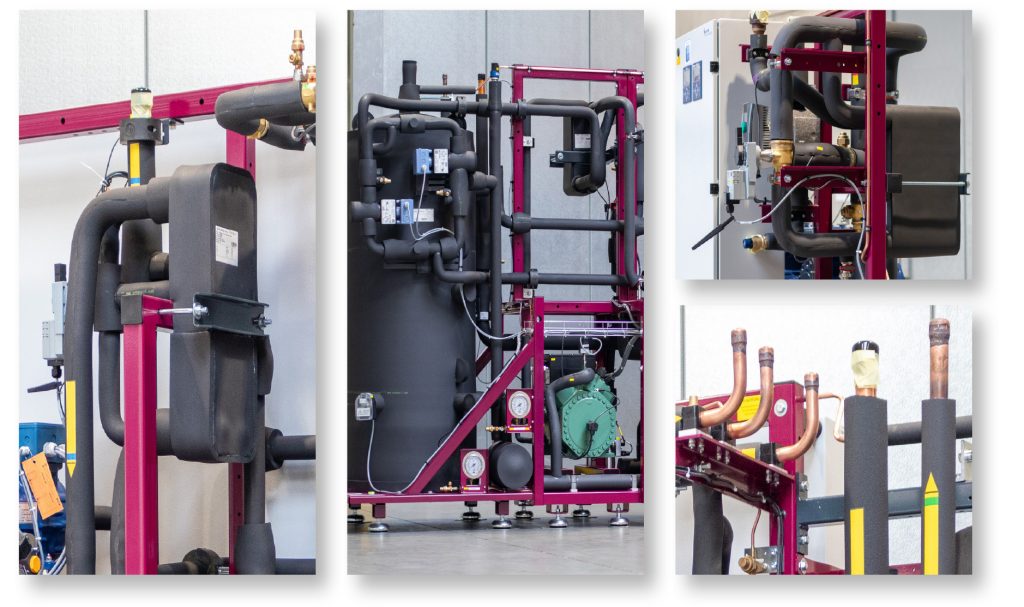

TEKO has developed the TECO2nditioner. This is installed to protect the compressor from damage and significantly extend its lifespan. The technology ensures that the compressor‘s suction temperatures are reduced and kept constant, preventing the oil used for lubricating the compressor from getting too hot. Compared to the commonly used air cooling, this solution is more energy-efficient and space-saving. Another major advantage of the TECO2nditioner is the preservation of performance from heat recovery, which would otherwise be released into the environment when using an air-cooled reheater. TEKO‘s patented technology significantly reduces CO2 emissions.

In the ROXSTAsmart, TEKO optionally offers a parallel compressor that increases efficiency and reduces consumption by about 12 % per year compared to the standard version, depending on environmental conditions. TEKO has recognized the international market‘s need for this technology, especially in regions with high ambient temperatures, and has successfully responded to it.

In the ROXSTAsmart, TEKO optionally offers a parallel compressor that increases efficiency and reduces consumption by about 12 % per year compared to the standard version, depending on environmental conditions. TEKO has recognized the international market‘s need for this technology, especially in regions with high ambient temperatures, and has successfully responded to it.

„The ROXSTAsmart not only offers our customers an efficient energy-saving solution but also improved ease of maintenance,“ explains product manager Patricc Schierbaum. „With this innovative improvement, we provide our customers with numerous benefits that greatly facilitate machine operation and maintenance.“

When installing a new CO2 system, many refrigeration engineers face the problem of piping leading out of various parts of the machine. TEKO will now install the pipes in one direction (upwards). This results in several advantages: Simplified machine installation, a smaller distance to the wall due to upward pipe alignment allowing for a more space-saving positioning of the ROXSTAsmart in the room. Additionally, during maintenance and repair work, technicians can easily access individual components without having to navigate around pipes.

„During the design planning of the ROXSTAsmart, more space was intentionally left between individual components to simplify service and maintenance tasks,“ reports Patricc Schierbaum. If technicians previously struggled to remove a component such as a liquid filter or coalescence cartridge, quick access is now possible due to increased spacing between components. Another benefit: faster maintenance leads to reduced service costs.

With the new features of the ROXSTAsmart, TEKO has developed innovations in refrigeration systems that meet demanding requirements for improved serviceability, plant safety, longevity, and increased energy efficiency. The ROXSTAsmart thus offers a forward-thinking solution for refrigeration engineering companies and their customers.

For detailed technical information and details about our CO2 products, we recommend consulting our brochure.

News

News