ROXSTA meets Kellner sound insulation housing

The especially soundproof solution for outdoor installation

In light of the summer temperatures, we have equipped our ROXSTAcube and ROXSTAsmart CO2 series with an especially soundproof housing for outdoor installation. This means that neighbours can work with the windows open or enjoy a break outdoors undisturbed: Thanks to the Kellner sound insulation housing, you can barely hear a sound from the running unit.

The effective and smart construction of the enclosed housing reduces the sound level by up to 27 dB(A). See for yourself in our video:

Video “Soundcheck Kellner sound insulation housing”

Advantages of the Kellner sound insulation housing:

- Easy operation

- Flexible equipment installation

- Weatherproof, storm-proof & rainproof

- Washable

- Optimum efficiency

- Innovative fan base

- Environmentally friendly materials

- Designed to meet the ever-increasing demands of noise regulations, communities and noise-sensitive neighbours

Benefit from our all-round carefree package. To simplify installation, the pipes are led directly out of the housing by TEKO and only need to be connected to the on-site pipe network.

Sturdy construction

The base frame construction is crafted from steel beams with a closed insulated steel tub as a base. Moreover, humming sounds are avoided thanks to the rubber mat flooring. The closed housing design consists of steel sheets combined with a waterproof carrier material and waterproof sound insulation panels. The sound insulation panels are flame retardant, in accordance with DIN 4102-B1.

For particularly simple, service-friendly operation, the housing is provided with sturdy door hinges and a door lock; in addition, thanks to the panels with handles, maintenance is easy and quick to carry out. The back can also be fitted with quick-release fasteners.

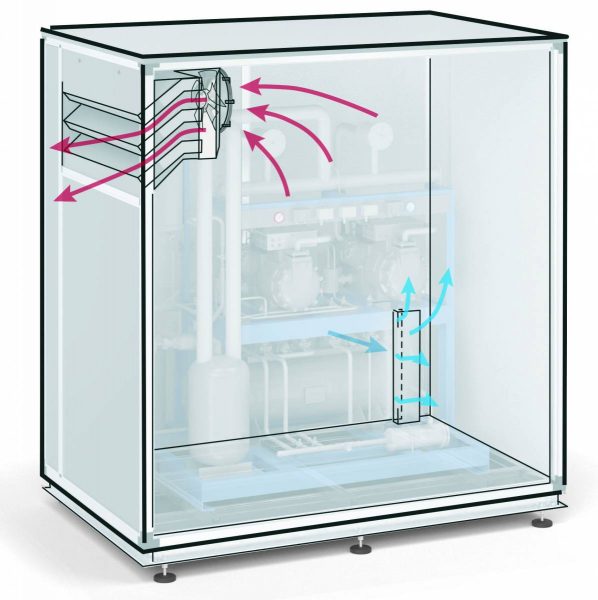

Optimal air discharge

The waste heat from the compressor is discharged via a quietly running exhaust air fan with an automatically regulated air volume of 0 to 2,000 m³/h. This is achieved via regulation of the rack unit, in accordance with the interior temperature. Air intake works via a labyrinth system, while discharge is carried out via a special sound-absorbing disk pack. This ensures optimum crossflow over the installed refrigeration unit.